The Maris Otter is almost gone. Seriously. And seeing as how it’s no longer cold outside a nice, simple, drinkable beer is required. Digging deep into Graham Wheeler’s Brew Your Own British Real Ale we came up with Big Lamp Bitter. Here we’ve adjusted the recipe for US/Standard measurements and added a few IBUs so that we don’t have any partial ounces of hops left-over.

Name: Big Lamp Bitter

Batch size: 5 gallons

Expected OG: 1.042

Expected FG: 1.010

Expected IBU: 30

Mash: 90m @ 152°F (Brew-in-a-bag)

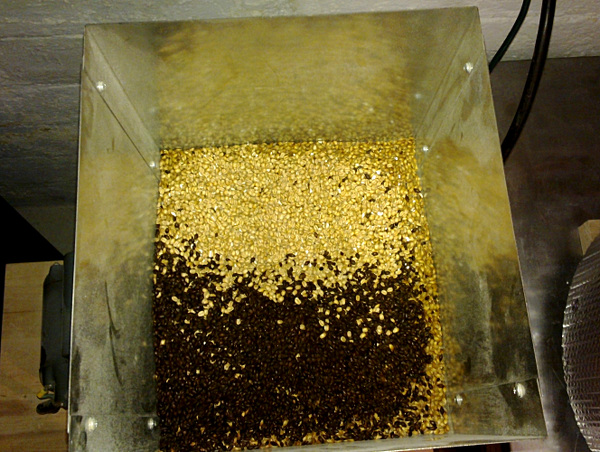

7.1 lbs Muntons Maris Otter 3L

6 oz Muntons Medium Crystal 60L

1 oz Goldings 5.5% AA @ 60m

Whirlfloc + yeast nutrient @ 10m

1 oz Fuggles 5.7% AA @ 5m

1 pack Safale S-05 Yeast

OK, so it’s not really a traditional bitter since we’re using S-05 yeast instead of a real British variety. And we’re only hopping for 60 minutes while Wheeler adds the hops at the start of the 90 minute boil for all his recipes. But whatever.

The Brew

This time we decided to use the Brew-In-A-Bag (BIAB) method instead of the traditional 3-vessel setup, mostly to see if we’d hit the numbers and if the brew day would be shorter. If you’re not familiar with BIAB, here’s the basic process:

- fill your kettle with the full pre-boil volume of water, plus whatever the grain will absorb

- heat all the water to the strike temperature (be sure to use a calculator for this, since there’s more water the temperature will drop less than regular methods after adding the grain)

- secure your bag in the kettle, then mill your grain and dump it into the bag

- stir the grain in the bag to break up dough-balls

- proceed with your mash

- pull out the grain bag, optionally rinse to extract more sugars, and squeeze to get as much liquid as you can

- proceed with your boil

In theory BIAB should take less time and less equipment, and for the most part that’s correct. We’ve actually done BIAB on this system before we finished building the HLT and the mash tun, so we have some data to go by.

We heated almost 9 gallons of strike water to 155°F and added the grain, which dropped the mash temperature to the expected 152°F and a pH of 5.6, which we adjusted to 5.4 with lactic acid. A half-hour into the mash the wort was 6°P. But now it was dinner time so we let the mash recirculate for a total of 2 hours. Upon return, after squeezing all the liquid we could out of the grain, we ended up with 8.5 gallons of 6.5°P (1.026) wort, while we actually wanted 8 gallons of 1.028 wort instead. Boil-off time!

After 30 minutes of boil-off, we had 8 gallons of 7°P wort (1.028) and started the real boil. Uneventful. 90 minutes later we had 5 gallons of 1.040 wort and an excellent hot break, all of which we dumped into the fermenter.

Did BIAB save us time? Yes, some, but not a lot. We keep trying to save time and never quite do it, so maybe the problem is us… Did we hit the numbers? No, not really, but we weren’t that far off. Had we mashed with less water, and boiled less vigorously, we may have gotten closer to the expected gravities. But did BIAB make cleanup easier? Definitely; only one kettle to scrub!

The Beer

10 days later, after fermenting around 65°F, we transferred the 1.009 beer to a keg. A week after that we had a light refreshing beer with a sessionable ABV of about 4%. It’s not very complex (obviously) but it’s a great summer beer. We’d brew this again, which means we Brewed It Right™.

10 days later, after fermenting around 65°F, we transferred the 1.009 beer to a keg. A week after that we had a light refreshing beer with a sessionable ABV of about 4%. It’s not very complex (obviously) but it’s a great summer beer. We’d brew this again, which means we Brewed It Right™.