Continuing the fine tradition of using stuff up, our next attempt at disposing of the year-old Maris Otter and British hops is a stout.

Name: Stout

Batch size: 5 gallons

Expected OG: 1.062

Expected FG: 1.016

Mash: 90m @ 152F at 1.3 qt/lb

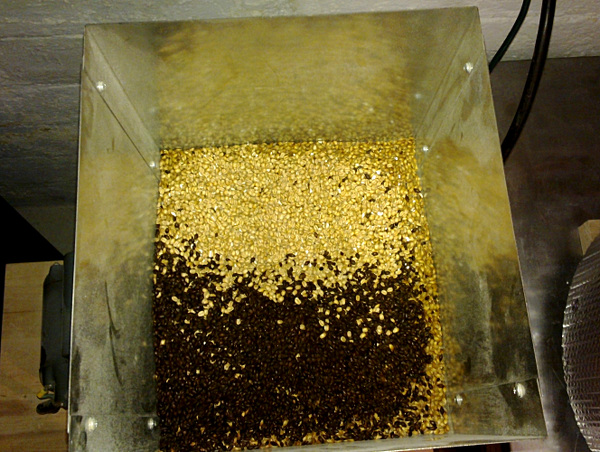

9.25 lbs Muntons Maris Otter 3L

1.0 lb Briess Chocolate 350L

12 oz Muntons Medium Crystal 60L

12 oz Muntons Dark Crystal 150L

6 oz Briess Black Malt 500L

6 oz Torrefied Wheat

1 oz Challenger 8.7% AA @ 60m

1 oz Fuggles 5.7% AA @ 15m

1 oz Challenger 8.7% AA @ 10m

Whirlfloc + yeast nutrient @ 10m

1 oz Fuggles 5.7% AA @ 5m

1 pack Safale S-04 Yeast

The Maris Otter, VIctory, and C60 are the oldest malt of the bunch, bought at the same time as all the hops in March 2013.

The Hose

A burst water hose provided the entertainment for the day. When building our setup we used a two-foot section of silicone high-temp hose (the same as we use between our kettles) from the wall-mounted water hookup to the cartridge filter mounted on our brewing bench. Hey, we already had it, so why not?

Unfortunately, standard silicone hose that home-brewers use has a max working pressure of about 10PSI. Most houses have a pressure of 40 – 60 PSI, so clearly this wasn’t going to work for long. A loud BANG followed by the sound of gushing water first scared the crap out of us, then horrified us as we scrambled to shut off the water and mop up the floor. The hose broke into three sections, with the center section burst right down the middle.

Carbon filters remove chlorine well, but only remove chloramine effectively when the flow rate is around 1 gallon per minute or less. We had drilled a 1/16″ hole in a quarter and placed this into the camlock which is hard-plumbed to our water supply, which reduces the flow rate. We thought it would also reduce the pressure in the hose, but apparently it takes a lot of pressure to push water through a carbon cartridge filter, at least more than silicone hose can take.

So we’ll be re-working our water supply to use high-pressure food-grade PVC hose from the wall hookup to the filter, since we don’t really want to clean up all that water again.

The Brew

With the fun all over, we lost a few degrees between the HLT and the mash tun when transferring the strike water, which we’ll have to compensate for in the future. Instead of mashing at 152F, like we intended, the mash stayed around 148F. But like we mentioned before, since the heat exchanger in the HLT was at 152F, some conversion still happens at the right temperature even if the mash is a bit low.

pH settled right on target around 5.3, from the strike water’s original pH of 7.0. Since the recipe uses a fairly high percentage of dark grains, it’s not surprising the mash pH dropped this low.

Continuing a tradition, we batch sparged for a third time. For the first batch we ended up with 5.25 gallons at 13.5 Plato (1.055). We added another 4 gallons of 152F water and recirculated for a few minutes, and then drew off 4.5 gallons at 5.5 Plato (1.022) for the second batch. Combining the entire first batch and 2.25 gallons of the second batch gave us 7.5 gallons of 10.5 Plato (1.042) wort to start the boil.

After the boil, we used our new whirlpool arm to circulate wort from the boil kettle through the pump, to the counterflow chiller, and back to the kettle. We then drained the boil kettle directly into a keg which we oxygenated and then pitched the packet of S-04 without rehydrating. This procedure does increase the risk of infection, since chilled wort is in contact with more surfaces (boil kettle, pump, chiller, hoses) than our usual direct-to-fermenter procedure.

Our whirlpool produced a somewhat slower whirlpool than we were hoping, but it did have the desired effect. All the trub (hop bits, grain bits, hot break, and cold break) concentrates in the middle due to the magic of physics. We then drain clear wort from the side, using a 90 degree side pickup, leaving the junk in the middle.

In the end, we got 5 gallons of 14 Plato (1.060) wort into the fermenter, about what we expected. Thankfully we put the keg into a spare plastic dishpan, since we woke up the next morning to foam and splatter out the airlock, despite using Fermcap S. Didn’t loose much beer, but next time we’ll just put less wort in the keg.